Manufacturing Mania

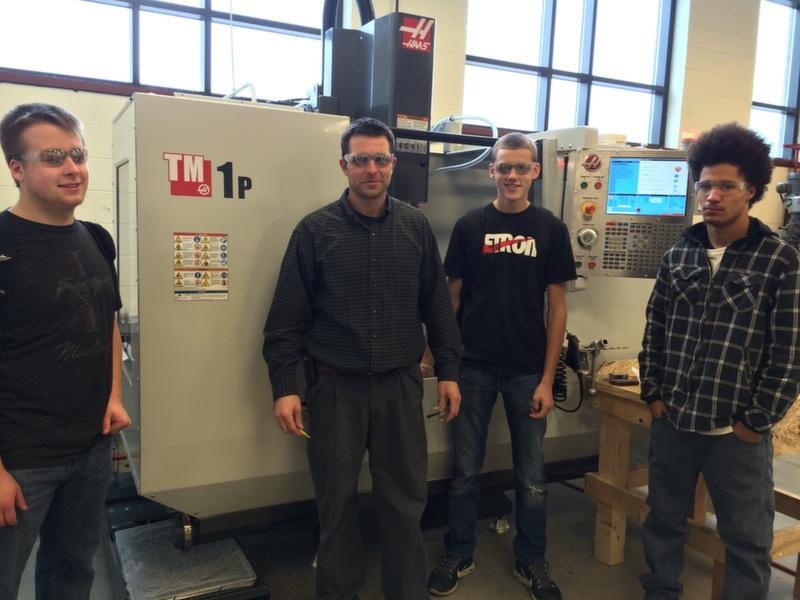

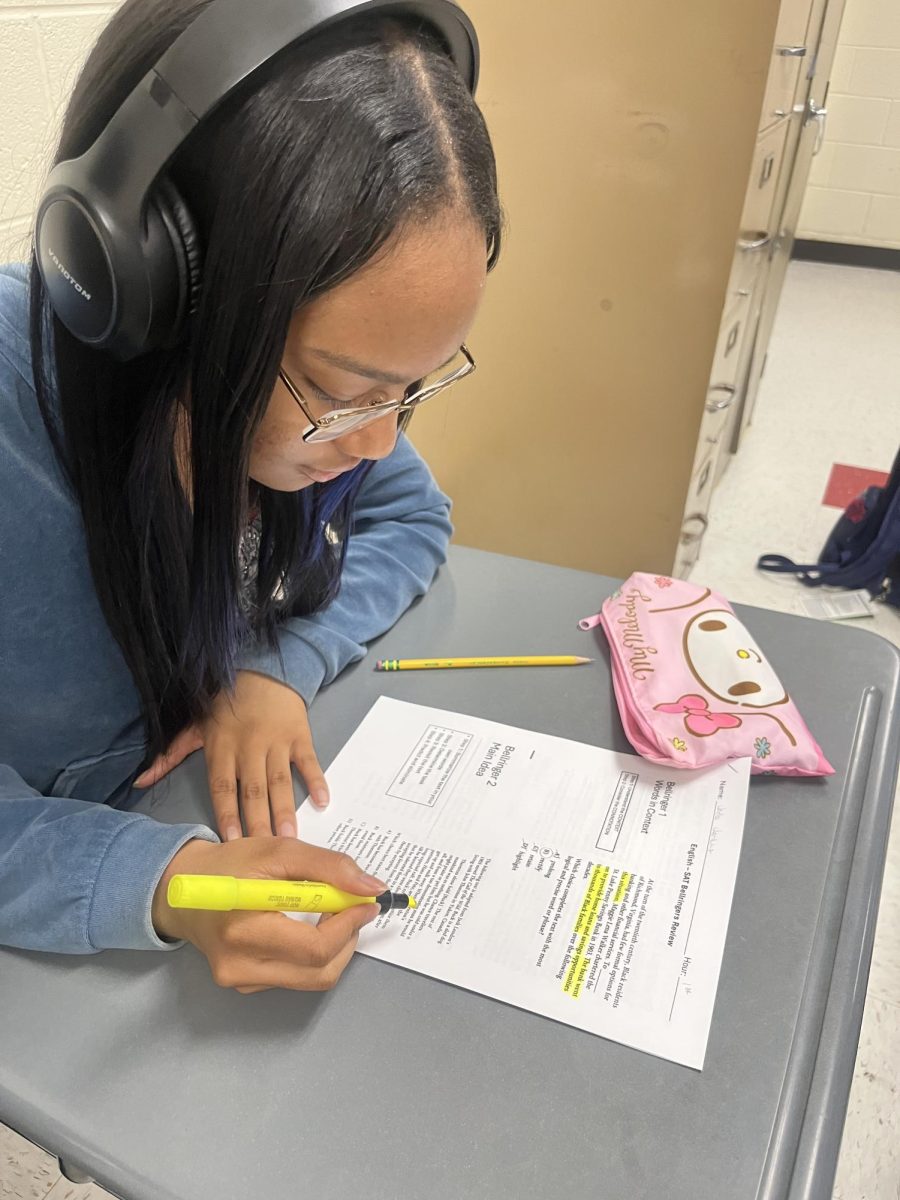

Teacher Matthew Komarowski and students demonstrate proper safety procedures with the new CNC machine.

December 19, 2014

As graduation advances for high school students in Michigan, there has been a noticed effort for recruitment in manufacturing careers. Aiming more specifically towards 11th grade students, manufacturers have teamed up with colleges and local high schools to attract young people in this forgotten trade. Why? The current workforce in manufacturing will be reaching their age of retirement, because of this, they will need competent employees to fill the openings. The MAT² program (Michigan Advanced Technical Training) was set into place in order to fulfill that request.

The MAT² program is an innovative system of learning, directed in a more hands-on environment relating to apprenticeship careers. The Michigan government, present in the Michigan Economic Development Corporation, works with industries, such as Volkswagon, Detroit Diesel, and Borgwarner, to enlist students into a three year commitment of training. The training can take place in many methods. The prime method being alternating blocks of eight weeks of class study then eight weeks of on-the-floor training. Another arrangement, promoted by Jackson College, is to offer a co-op class to juniors so that in their thirteenth year of school they will graduate with an associate’s degree and a job that can pay from $25 to $45 an hour. Career camps such as these have been regarded as full proof as they are still a common process in European states as well.

Unlike other careers where the student must pay for their own schooling, this program allows future manufacturers to completely benefit from this program. Schooling is paid for from the partner manufacturing company and almost always guarantees a job after graduation. Students are paid whilst in training and receive real experience as an apprentice or pre-journeyman.

All of this ties in with Roseville High School’s newest machine in the tech wing. The CNC machine, or computer numerical cutting machine, is the latest addition to our school’s collection. It is a larger unit which holds multiple smaller machines, varying from laser cutters, drills, grinders, and even water jet cutters, all of which work together to complete one task assigned by the programmer. Capable of cutting a range of materials from wood, steel, plastic, and more, this machine is used heavily in the manufacturing field. It can be programmed through code or controlled manually by levers and pulls. Students in drafting can create a blueprint via 3-D programming and the CNC machine can create a physical copy. The machine wields three axes, XYZ, which may seem complicated initially, but not when compared to more advanced five axes models. It’s great for novices to work hands-on with this machine now rather than later. The new CNC machine can be found in Komarowski’s room.

So for students not quite sure what’s left after high school or just so happen to be interested in vocational education, a job in manufacturing may be for you. For more information on job opportunities or how to apply to MAT², visit www.mitalent.org or contact the company at 1.888.522.0103 or [email protected].